CONTEXT:

Mass-production produces things with a low ‘unit cost’ through investment in complex manufacturing processes. This equates to ‘affordable products’. Most of these processes are variants of moulding or casting. Understanding the principles behind moulding and casting and how they shape a product is a critical step towards understanding the relationship between processes and product design.

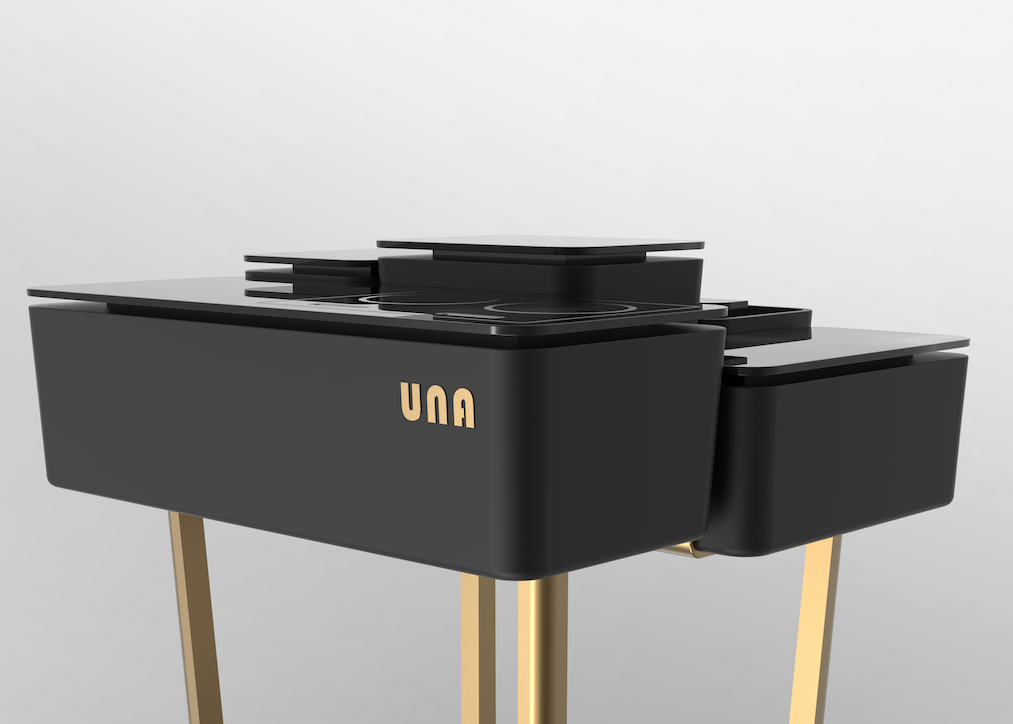

The main deliverable of this project is a vessel of your own choice through digital design processes - digital manufacturing and CAD.

DESIGN:

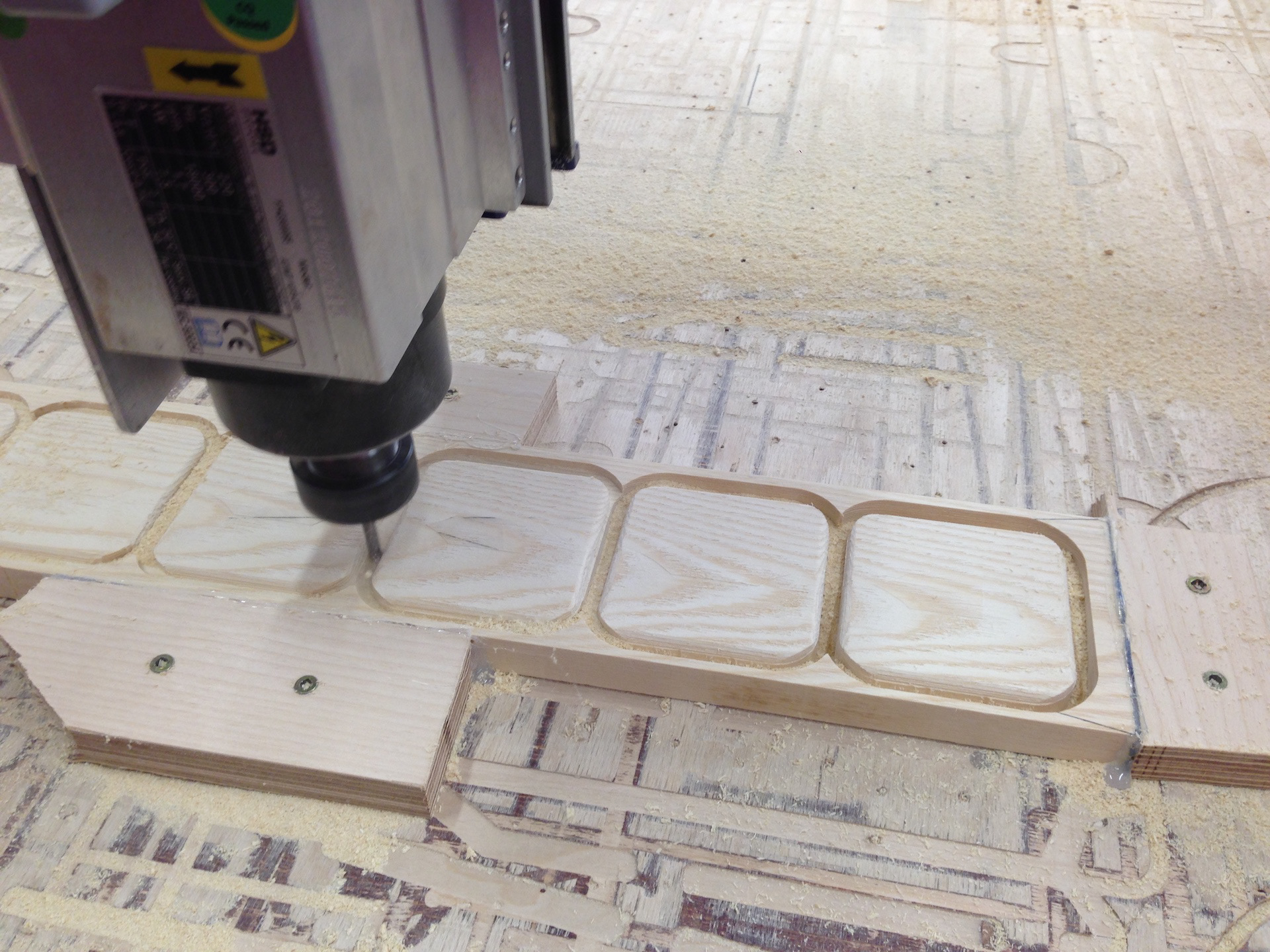

Skriva brings concrete and timber together to make a container for stationery. The concrete is cast in two halves using two separate moulds made from plaster. The base was CNC milled to precisely execute the transformation between rounded edges and sharp-edged corner.

MANUFACTURING:

Mould made from plaster.

Silicon spray and 'Petroleum Jelly' were used as release agents.

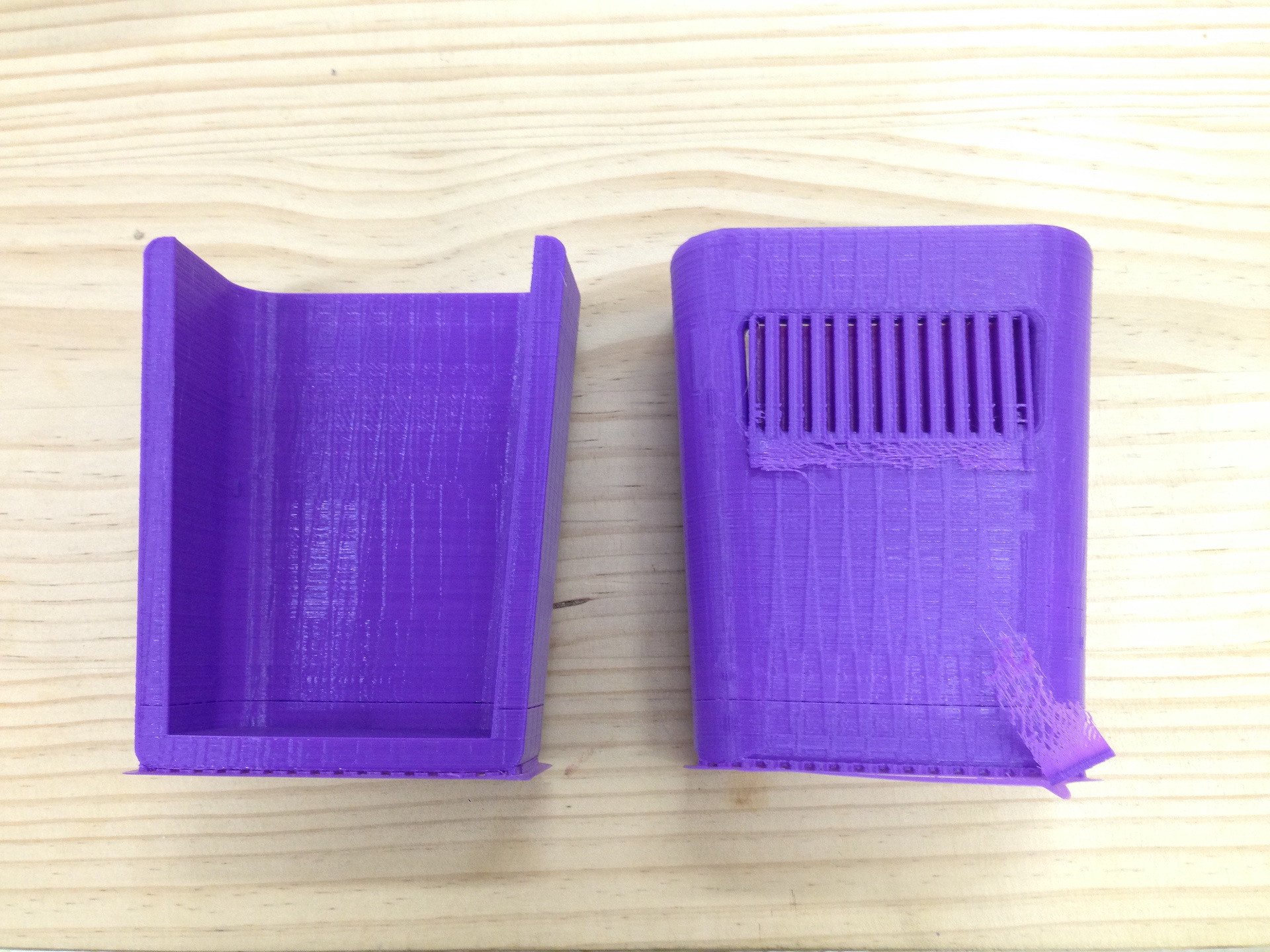

Mould was made from 3D printed parts.

Base was CNC milled from Ash timber off-cuts.

FINAL DESIGN: